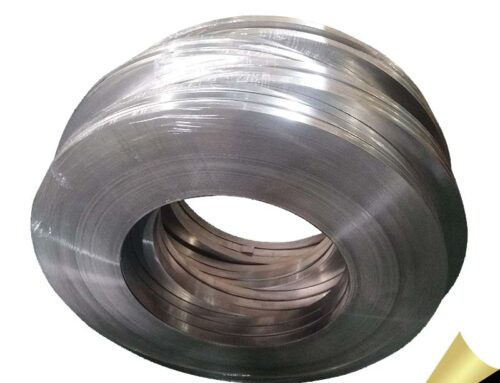

316ti Stainless Steel Strip

- Certification:ISO.SGS.BV

- Standard:GB JIS ASTM UNS KS BS EN IS IS CNS

- Grade: 0Cr18Ni12Mo3Ti 06Cr17Ni12Mo2Ti SUS316Ti 316Ti S31635 – 1.4571 04Cr17Ni12MoTi20

- Technical Treatment:Cold Rolled,Hot Rolled

- Thickness:0.01mm-25mm or customized as required

- Width:3mm-2500mm or customized as required

- Length:Customized as required

- Surface Finish:BA.2B.2D.4K.6K.8K.NO.4.HL.SB.Embossed

316Ti stainless steel is a titanium-stabilized version of 316 stainless steel. It has the following properties and characteristics:

1. Improved high temperature resistance. The addition of titanium to 316 stainless steel improves its high temperature strength and resistance to sensitization. 316Ti can withstand service temperatures up to 800-1500°C, higher than 316 stainless steel. So it is suitable for high temperature applications such as furnace parts, burner components, etc.

2. Better corrosion resistance. The titanium addition helps stabilize the microstructure of 316Ti and prevents carbide precipitation at the grain boundaries. This enhances its corrosion resistance in high temperature and harsh environments, especially resistance to sensitization corrosion.

3. Higher strength. 316Ti stainless steel typically has a tensile strength of 515-620 MPa, higher than the 505 MPa for 316 steel. The yield strength of 316Ti is also slightly higher than 316.

4. Limited work hardening. Due to the effect of titanium, 316Ti stainless steel has limited work hardening characteristics. It can get work hardened more slowly during operations like stamping, bending and drawing. This makes it suitable for applications requiring extensive cold working.

5. Difficult to machine. The titanium addition increases the hardness and strength of 316Ti, making it more difficult to machine compared with 316 stainless steel. More advanced machining technologies and tools are required for processing and finishing 316Ti.

6. Higher cost. The titanium addition means 316Ti is more expensive to produce and purchase compared with regular 316 stainless steel. For most applications, 316 steel is a more cost-effective choice.

In summary, 316Ti stainless steel has enhanced high-temperature strength, oxidation and sensitization corrosion resistance due to its titanium addition. It is suitable for high temperature and harsh environment applications where regular 316 steel cannot meet the performance requirements. However, its work hardening characteristics, machinability and cost are not as good as 316 stainless steel. So 316Ti is mainly used where its superior properties can be utilized and justified for critical applications.

You can order 316Ti stainless steel strip or 316Ti stainless steel sheet according to your production.

You could order 316Ti stainless steel strip with below different surface treatment

| Description | Abbr | Features | Manufacturing Process | Application |

| Original surface | No.1 | Silver-white color | Hot rolling, followed by heat treatment and pickling | Industrial tanks, chemical industrial equipment, etc. with a thickness of 3.0mm-10.0mm and no need for surface gloss |

| Dull surface | 2D | No gloss | Hot rolling + annealing shot peening + cold rolling + annealing pickling | Used for deep drawing processing, such as automobile components, water pipes, etc. General-purpose material, commonly used in industry |

| Matte surface | 2B | Slightly glossy silver-white with a flatness of 0.39 microns and a roughness of H degree | Hot rolling + annealing shot peening + cold rolling + annealing pickling + temper rolling NO.2D treatment, followed by final light cold rolling with a polishing rod |

Used for tableware, building materials, etc. After surface treatment to improve mechanical properties, it can be used for almost all purposes. |

| Satin finish | No.3 | Good gloss with discontinuous coarse lines | Products ground with a 100-120 grit abrasive belt | Used for building interior and exterior decoration materials, electrical products, and kitchen equipment, etc. |

| Satin finish | No.4 | Good gloss with discontinuous fine lines, finer than No.3 | Products ground with a 150-180 grit abrasive belt | Used for bath, building interior and exterior decoration materials, electrical products, national housing equipment, and food equipment, etc. |

| Satin finish | NO.240 | Good gloss with discontinuous fine lines, finer than No.4 | Products ground with a 240 grit abrasive belt | Used for bath, building interior and exterior decoration materials, electrical products, kitchen equipment, and food equipment, etc. |

| Satin finish | NO.320 | Good gloss with discontinuous coarse lines | Products ground with a 320 grit abrasive belt | Used for construction materials, kitchen utensils, etc., or food equipment |

| Satin finish | NO.400 | Silver-gray color with hairline texture | Products ground with a 400 grit abrasive belt | Used for construction materials, kitchen utensils, etc., or food equipment |

| Brushed surface | HL | Polishing with appropriate grinding material with gradient for 2D or 2B products to achieve continuous grinding pattern | Products continuously ground with an appropriate grit polishing belt to create continuous grinding flower patterns (subdivided into 150-320 grit) | Used mainly for building decoration, elevators, building doors, panels, etc. |

| Bright surface | BA | Excellent surface gloss with high reflectivity | Typically, a bright heat treatment surface with high reflectivity | Used for household appliances, mirrors, kitchen equipment, decorative materials, etc. |

| Mirror surface | 6K | Slightly worse than mirror finish | Coarse grinding and polishing | Used for mirrors, decorative panels |

| Mirror surface | 8K | Mirror-like | Grinding and polishing | Used for mirrors, decorative panels |

- Kitchenware and cookware: 202 stainless steel is often used to make pots, pans, and other cooking utensils because of its corrosion resistance and high-temperature strength.

- Automotive components: 200 stainless steel is used in the manufacturing of automotive components, such as exhaust systems and trim, due to its durability and corrosion resistance.

- Construction: 201 stainless steel is sometimes used in the construction of buildings and structures, particularly in areas that are exposed to high levels of moisture or salt, such as coastal regions. It is also used in the production of decorative trim and railings.

- Industrial equipment: 200 stainless steel is often used in the manufacturing of industrial equipment, such as heat exchangers and boilers, because of its corrosion resistance and high-temperature strength.

Packaging

When transporting stainless steel raw materials, the packaging is very important. Proper packaging can protect stainless steel raw materials from damage and corrosion. In addition, appropriate packaging can also ensure that stainless steel raw materials will not be cross-contaminated with other materials, such as steel rust, dust, and other impurities, during transportation.

We usually use wooden pallets or wooden boxes to transport stainless steel materials. As a professional stainless steel manufacturer in China, we also add partition paper, frames, and straps to ensure that the materials are not damaged. These materials are also made of stainless steel to avoid contaminating the raw materials. All we do is ensure you can have good stainless steel material from China.

Facilities

Still Steel boasts a strong technical team, advanced production equipment, a complete set of quality inspection equipment, and strict adherence to industry standards. As a Chinese stainless steel supplier, we provide an abundant supply of stainless steel strips, coils, and sheets at competitive prices. Additionally, we offer customizable solutions to meet unique specifications, no matter where you from,Vietnam , UK, Korea.

FAQ

Yes, of course. Common small size is free for your evaluation.

You can tell us material grade, thickness, size as width & length, surface finish and quantity.

Surely, we sincerely welcome you come to China and view our factory by yourself.

Yes, we understand your concerning and have confidence in our products.Our products has been approved by many 3rd part, such as SGS, ITS, BV.

Based on years of exporting experience, we can quote you FOB, CFR, CIF, DDP, express and dropshipping.

We treasure your trust and return no MOQ for you.

Surely, large quantity could bring a low cost.

Surely, we provide ink printing and laser marking for you.

With considerable quantiry, the packaging is also customized.

Normally the delivery time is 10-25 days.

Contact

Still Steel Material Co., Ltd never stops moving ahead to do more and better for our clients. We well understand the importance of delivery on time, because it’s not only our only promise to you but also your promise to the client. High-quality material could make production safer, reduce defective rates, and also good impress your pursuit of quality.

What we focus is only making good stainless steel material for you, 201, 202, 304, 310S, 316, 409,410,420,430 stainless steel here, with specified thickness and width, strip or sheet, with film coated or not,

Different surface treatments such as satin, mirror, 6k, and 8k.

Now our products have been exported to many countries, such as Vietnam, Thailand, Malaysia, Philippines,UAE,Pakistan and others.